Email:zyzsales02@zhuoyangzk.com

Battery production

Vacuum and leak detection solutions for clean energy

Mixing - pulping with active materials, which is the source of positive and negative battery materials

Slurry mixing refers to the process of mixing and stirring the positive and negative active materials, conductive agents, binders and dispersants according to a certain ratio. It is the first process of battery cell production and can be subdivided into feeding and mixing. , the quality control of this process will directly affect the quality of the finished battery.

Feeding and mixing are very particular about the ratio of raw materials. In order to ensure accuracy and consistency, the equipment has been upgraded intelligently, which can realize automatic feeding, automatic weighing and measurement, and the accuracy is as high as 3/10,000. The high-speed dispersion core process technology adopted by the equipment, the speed reaches 4500 rpm. It is transported through a fully closed pipeline, strictly controlling dust, ensuring the uniformity of the slurry and enhancing the safety and environmental protection of the slurry transport process.

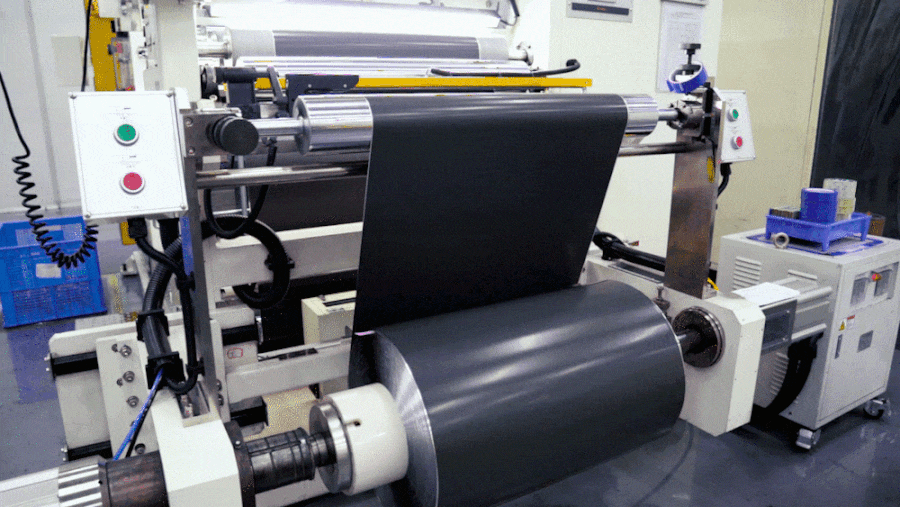

Coating - coating the slurry on copper foil for the manufacture of battery positive and negative electrode sheets

From the point of view of the process flow, coating is a key process in the preparation of the cell. The uniformity, consistency, alignment, baking stability, binder diffusivity, and areal density stability of the coating are closely related to this. The quality of the coating is directly related to the quality of the battery.

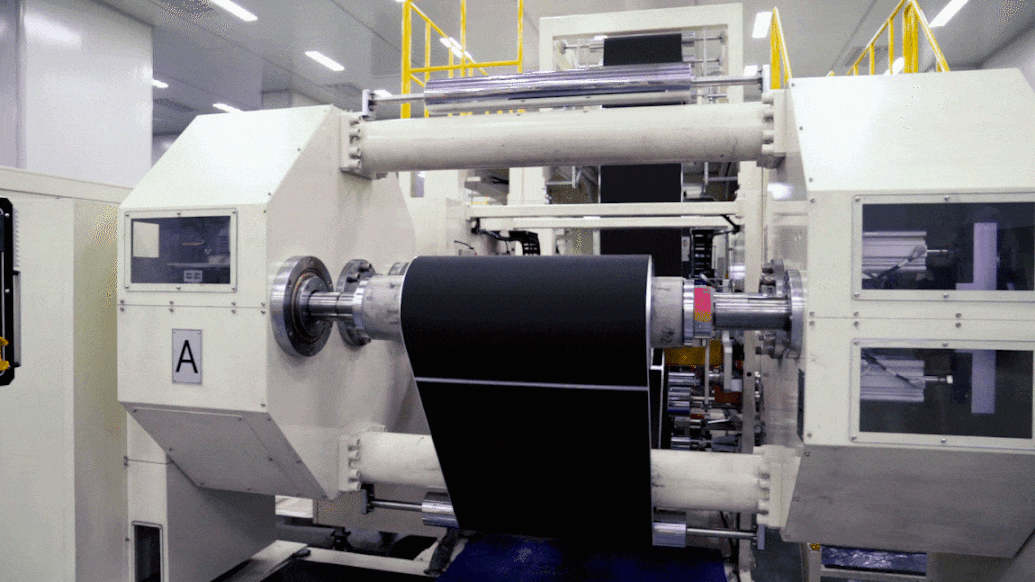

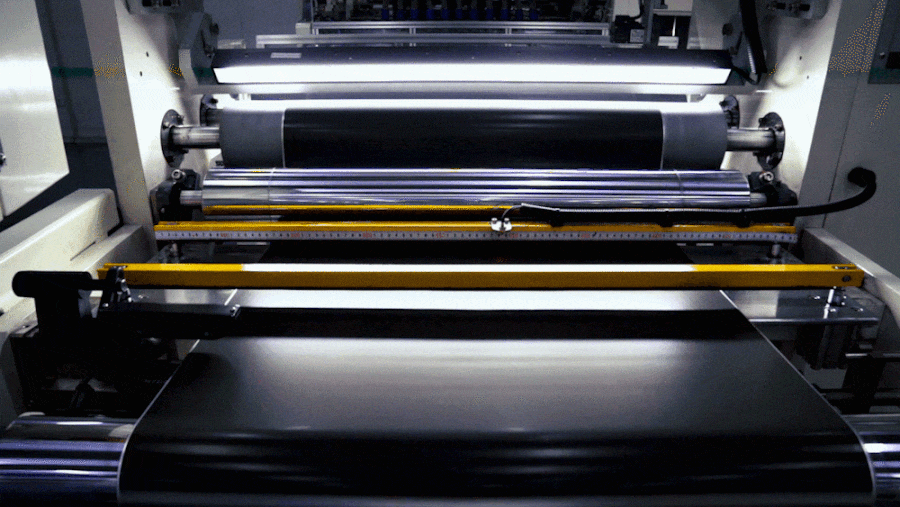

Rolling - pressing the positive and negative materials more tightly

Rolling is to roll the pole pieces attached with positive and negative materials by rollers. On the one hand, it makes the coated material tighter, improves the energy density, and ensures the consistency of thickness. On the other hand, it will further control dust and humidity.

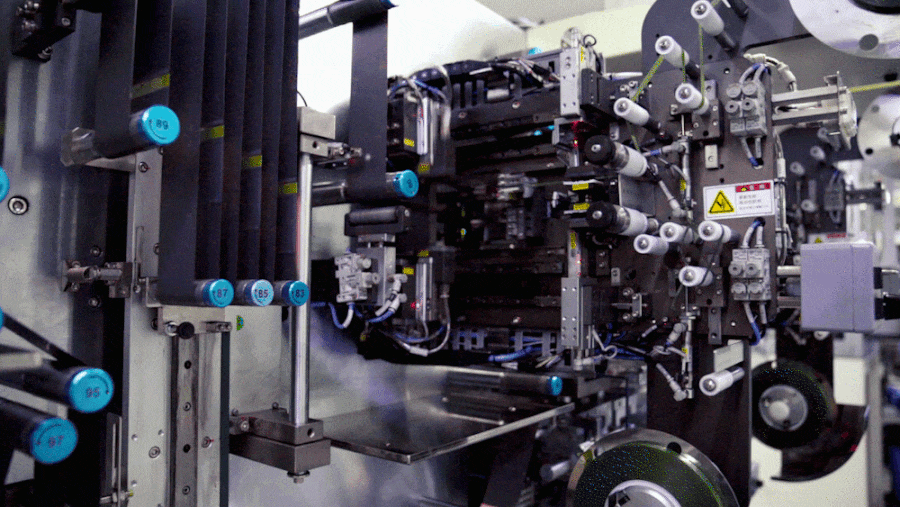

Slitting - cutting the pole pieces to the specified size

The blade cutting method is adopted, the precision is controlled within 0.1mm, and it is equipped with functions such as online CCD detection, automatic labeling, automatic recording of defective products, edge burr control, etc., to ensure the stability and safety of the pole piece quality.

Winding - forming the prototype of the shape of the cell

Winding is to wind the pole piece after slitting into a cylindrical core with a specified thickness. After the winding is completed, the prototype of the cylindrical battery is already available. Tianneng adopts three-axis winding technology in the winding process, which integrates production, winding, and short-circuit measurement. While improving production efficiency, it can ensure the safety and consistency of cells to the greatest extent.

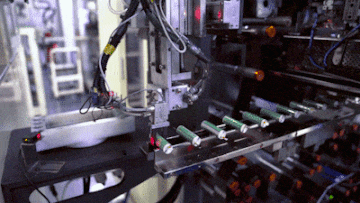

Loading - feeding the core and checking for defects

Through the intelligent loader, the automatic identification function of the bar code of the core is realized, the outer diameter of the core is automatically detected. The defective core is automatically removed to ensure that all qualified cores enter the next process.

Into the shell - put the core into the steel shell and put in the gasket

The automatic shell feeding machine can put the coil core after feeding into the steel shell, and complete the self-assembly of the insulating gasket. Dynamic punching, positioning, installation, inspection process. The equipment has automatic steel shell positioning function, and the pass rate is as high as 99.5%.

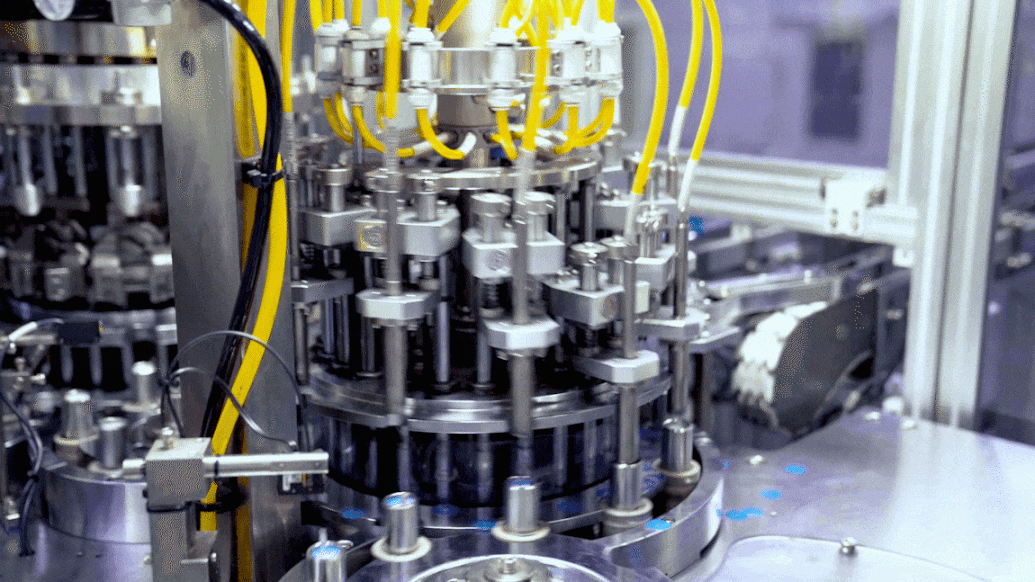

For leak detection of new energy vehicles, we provide leak detection solutions for the entire industry chain,

Including but not limited to:

From the detection of each component of the cell before the electrolyte is injected,

To the detection of the battery shell after the battery is injected into the package,

Then after the battery application,the inspection of the assembly components,etc.

For more informtion of leak detection, just contact me!

Whatsapp:008618655117306

Email:rebornzhou90@gmail.com

Hefei Young Vacuum Tech. Co.,Ltd