Email:EmilyZong28@gmail.com

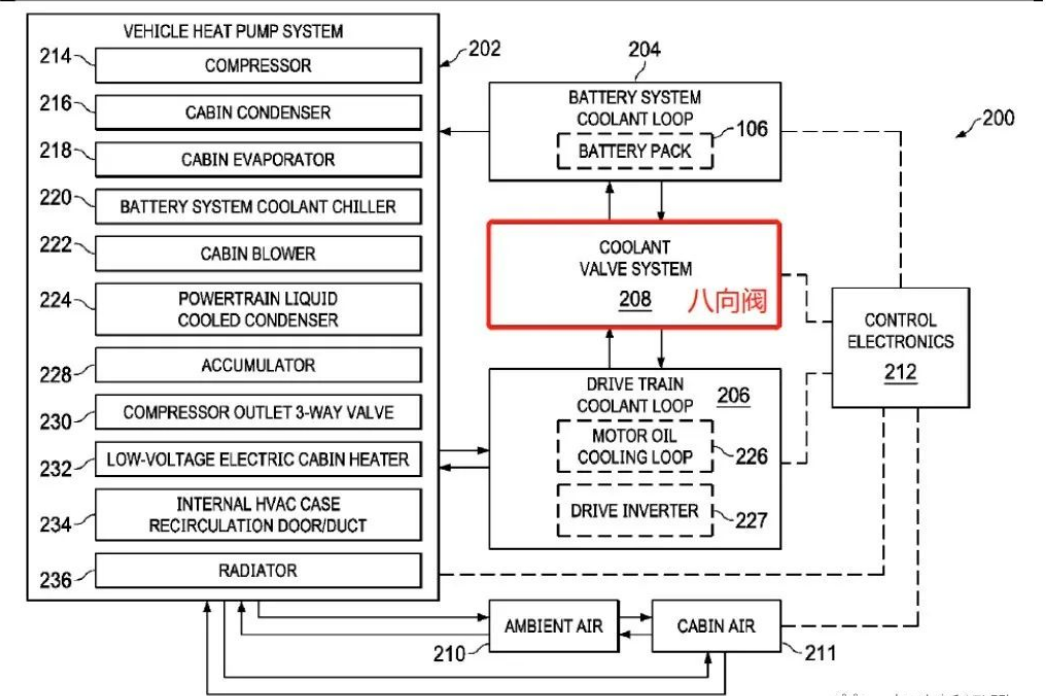

Heating in the cabin, providing suitable working temperature for the three-electric system leak test equipment, the thermal efficiency of traditional internal combustion engines can reach about 40%. Through the effective thermal management system, the waste heat generated by the engine can be recovered and provided to the cockpit for heating. However, new energy vehicles cannot use the heat generated by combustion. The mainstream heating solutions include air (wind heating) PTC, water heating PTC, and heat pump air conditioners.

The heating principle of the PTC thermistor heating system leak test system is simple. It relies on the current to pass through the resistance to generate heat. The PTC used in pure electric vehicles is a semiconductor thermistor. The characteristic of PTC is that the resistance value of the PTC material will also increase with the increase of temperature. This characteristic determines that in the case of constant voltage, the PTC heater heats up quickly when the temperature is low, and the resistance value increases after the temperature rises, and the current becomes smaller, the PTC consumes less energy, which keeps the temperature relatively constant.

PTC water heating is often combined with the motor cooling water circuit; air heating PTC is to directly install the PTC at the heater core of the cab, circulate the air in the car through the blower, and directly heat the air in the cab through the PTC heater. The structure is relatively simple.

PTC technology has the advantages of low cost, simple manufacturing process, and rapid heating, but the use of PTC to heat electric vehicles will seriously reduce the cruising range of the car, and the COP of PTC technology is less than 1, and the efficiency is low. In this context, heat pump technology is more concerned. From a principle point of view, the core principle of the heat pump is the reverse Carnot cycle. The work consumed by the heat pump can transfer the heat in the environment to the high temperature heat source. Its efficiency coefficient greater than one does not violate the first law of thermodynamics, that is, the law of conservation of energy, because The heat absorbed by the high temperature heat source not only comes from the work consumed by the heat pump, but also from the heat in the low temperature heat source (ie, the atmospheric environment). However, from the perspective of energy conversion, PTC technology only converts electrical energy into thermal energy, so the COP value can only reach 1 in the ideal case.

The efficient operating temperature range of power batteries is narrow, and the thermal management system is the key to maintaining battery performance and safety. 20-35℃ is the high-efficiency working temperature range of the power battery. If the temperature is too low, the charging and discharging power performance of the battery will decrease and the cruising range will be shortened. If the temperature is too high, 45℃ will cause the risk of thermal runaway of the battery, which will threaten the safety of the whole vehicle.

On the other hand, leak test machine electric vehicle power batteries require uniform temperature control. Excessive differences will cause internal consumption, reduce battery charge-discharge cycle efficiency, and affect battery power and energy performance. In severe cases, it will lead to thermal runaway, affecting system security and safety. reliability. In order to maximize the performance and life of the battery pack, thermal management of the battery is required, which usually requires a complex and sophisticated cooling circuit to maintain the battery cell temperature consistency and control the battery pack temperature within a reasonable range.

Hefei Young Vacuum Tech. Co.,Ltd